When you hear the phrase “inflatable structure,” the first image that comes to mind is likely to be a brightly colored bounce house or maybe the temporary buildings that were used for COVID testing or administering vaccinations during the pandemic.

But the future of inflatable structures is…well, out of this world.

Here, we’re going to look at two examples. One is NASA’s Low-Earth Orbit Flight Test of an Inflatable Decelerator (LOFTID), including a review of what preceded that work, that was launched in early November 2022 to demonstrate inflatable heat shield technology. The other is work being done by Pneumocell, an organization based in Vienna, Austria, led by architect Thomas Herzig, to produce prefabricated ultralight inflatable architecture that could be used for lunar habitat.

NASA

“I was working on the Mars Smart Lander in 1999,” says Steve Hughes, who is involved in the LOFTID work in his role as aeroshell system lead. “We were having trouble because the payload, as usual, was getting heavier than originally designed. We were approaching the limit of what the aeroshell could deliver safely to the planet surface.

Early tests included three Inflatable Re-entry Vehicle Experiments (IRVE), explained in a paper written by Hughes and colleagues for a conference presentation. “Inflatable aeroshells offer several advantages over traditional rigid aeroshells for atmospheric entry,” the report states. “Inflatables offer to increase the payload volume fraction of the launch vehicle shroud and the possibility to deliver more payload mass to the surface for equivalent trajectory constraints. An inflatable’s diameter is not constrained by the launch vehicle shroud.

“The resultant larger drag area can provide deceleration equivalent to a rigid system at higher atmospheric altitudes, thus offering access to higher landing sites,” continues the report. “When stowed for launch and cruise, inflatable aeroshells allow access to the payload after the vehicle is integrated for launch and offer direct access to vehicle structure for structural attachment with the launch vehicle.”

After nearly two decades of development of Hypersonic Inflatable Aerodynamic Decelerator (HIAD) technology, the LOFTID orbital flight test was conducted in late 2022. The return from orbit demonstration paves the way for its use on future missions, according to NASA. The LOFTID reentry vehicle was the largest blunt body aeroshell to ever go through atmospheric entry.

Exceptionally strong structure

The HIAD design consists of an inflatable structure (IS) that maintains its shape against the drag forces and a flexible thermal protection system (FTPS) that withstands the heat of reentry. It’s built with a stack of pressurized concentric rings, or tori, that are strapped together to form an exceptionally strong blunt cone-shaped structure. The tori are made from braided synthetic fibers that are stronger than steel and can withstand temperatures in excess of 750 F (400 C).

According to NASA, the system is constructed with three layers: an exterior ceramic fiber cloth layer to maintain the integrity of the surface, a middle layer of insulators to inhibit heat transmission, and an interior layer that prevents hot gas from reaching the inflatable structure. Because it is flexible, it takes up less room in the rocket and allows the design to be scalable.

For its 2022 test, about an hour after launch on a United Launch Alliance Atlas V rocket, LOFTID inflated and deployed in space. After being released by the Centaur upper stage, the heat shield began its reentry through Earth’s atmosphere, entering the atmosphere at roughly 18,000 miles per hour. LOFTID created enough drag to slow to less than 80 miles per hour by the end of its demonstration. At this point, LOFTID’s onboard parachutes deployed, carrying the heat shield to a gentle splashdown in the Pacific Ocean.

NASA said the team recovered the LOFTID aeroshell within a few hours, and early indications show that the demonstration was successful. In addition to achieving its primary objective of surviving the intense dynamic pressure and heating of reentry, it appears that the aft side of the heat shield—opposite LOFTID’s nose—was well protected from the reentry environment. This suggests that inflatable aeroshells can keep payloads safe during atmospheric entry.

NASA expects a full study of LOFTID’s performance to take about a year. The results of the LOFTID demonstration will inform future designs for inflatable heat shields that could be used to land heavier payloads on planets with atmospheres.

Pneumocell

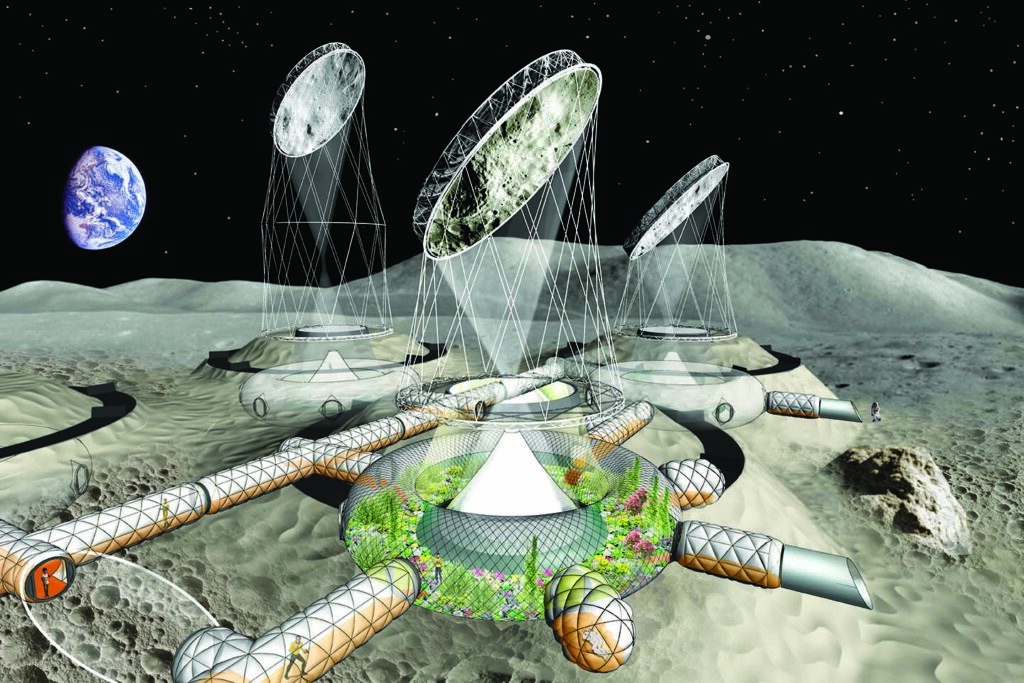

According to the Vienna, Austria-based company Pneumocell, using inflatables for space travel is only the beginning of their potential. As the designer and owner of the patent rights, Pneumocell architect Thomas Herzig has plans to use them as structures on the moon. But for now, his work involves an ultralight inflatable membrane structure that is manufactured and tested only on Earth under ideal conditions, he says.

While the primary structure is an inflatable, all the rest of the building material that protects the habitat from cold, radiation and meteorites comes from the lunar surface in the form of loose rocks and dust, also known as regolith, which will be deposited on top of the inflatable structure.

Since there is no atmosphere on the moon, an inflatable structure inflated up to half Earth-atmospheric pressure could support a deposit of regolith up to 16 meters high on the moon. “But 4 meters of deposit are sufficient for protection,” says Herzig. “Since the interior air pressure has a lot more effect on the building structure than the weight of the deposit, rigid walls and ceilings are unnecessary to hold the structure.”

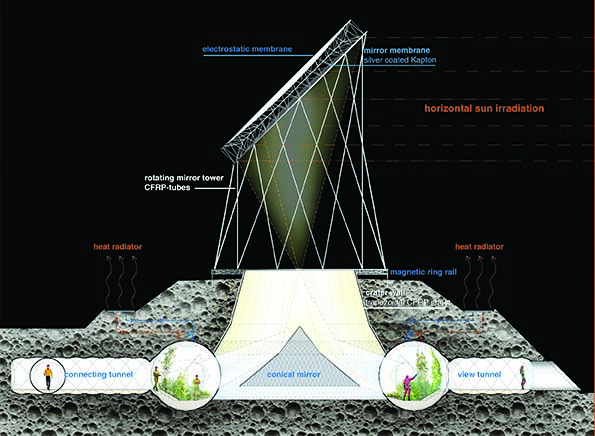

The most essential part of the design is the toroidal, or doughnut-shaped greenhouses, where oxygen, water and food would be self-sufficiently produced and recycled. All other rooms are linked to these greenhouses. “Our design enables natural sunlight to enter the greenhouses, while cosmic particle radiation is blocked out,” says Herzig.

The greenhouse features an open crater in the center. A rotating mirror reflects the sunlight down into the crater, where it is reflected again by a nearly cone-shaped mirror into the greenhouse. “Thus, inside we create a natural environment, where plants, microorganisms, animals and humans live in symbiosis,” he says.

Material challenges

The materials of the habitat structure and the mirror need to feature the right optical properties as well as withstand many influences: extreme temperatures, mechanical stress, UV radiation and cosmic particle radiation.

According to Herzig, optional membrane materials for the greenhouse structure include aliphatic UV-resistant thermoplastic polyurethane (TPU) film, and Mylar®, also known as BoPET (biaxially-oriented polyethylene terephthalate).

For the ropes, Herzig explains that Kevlar® has the highest tensile strength of all fibers, but it is not UV-resistant, so it can’t be used for the greenhouse structure, which is exposed to sun radiation on the inner side. “Dyneema® features a bit less tensile strength than Kevlar, but has better tensile strength in relation to its weight and it is UV-resistant,” he says. “This clearly qualifies Dyneema as the best candidate for the rope structure.”

For the mirror, Kapton® membrane material was chosen. “Both Mylar and Kapton already are approved in space, but the latter shows a better resistance to cosmic particle radiation in the long term,” he explains. “While the greenhouse window mostly receives radiation from the visible to infrared spectrum reflected from the mirror, the mirror itself receives all of the cosmic particle radiation.”

But the biggest challenge currently lies in determining what the inflatable structure itself can be constructed out of. Kapton cannot be used for airtight inflatable structures because it can’t be welded, he says.

“Nobody has built large inflatable structures with Mylar yet, and while I have experience with TPU, it gets quite stiff below -60 C [-76 F],” says Herzig. “We can take precautions on the moon that it would not get that cold, but we have no experience with TPU in outer space. We would need to test each of the materials to find out which is better.”

Whatever material is chosen will have to be durable enough to withstand prolonged contact with the incredibly sharp particles of dust and rock that are found on the lunar surface. Earth has wind and rain to grind off the rough edges of rocks, but as these conditions do not exist in space, even the tiniest particle of dust is sharp enough to penetrate traditional fabrics.

Herzig believes he has a two-part solution to this problem for Pneumocell’s inflatable structures, which he outlined in his report titled, “ESA-(OSIP)-study for a MOON HABITAT.”

“With a sieve, big sharp pieces can be separated from the regolith. As a second step, regolith can be stirred in a rotating container, similar to a concrete mixer. From permanent movement and friction, the grain will lose its sharp edges and get smooth. Only smoothed regolith should be shoveled into the construction pit and be used for the first 20cm deposit layer closest to the membrane.

“Additionally, a 1cm thick foam protection layer could cover the membrane structure, or as an alternative the outer membrane layer could be just thicker to reduce the risk that a small sharp particle could make it through all the membrane.”

But Herzig cautions that all these plans still need to be carefully tested on samples and prototypes, and even that process presents challenges. “There is moon regolith simulant available, but that only simulates the chemical composition and grain size, not the sharpness,” he explains.

As of now, no one knows for sure how long it might take to turn these plans into reality.

“So far nobody has a concrete plan to build a lunar habitat,” says Herzig. “We need more budget to continue our research, to build a prototype here on Earth, and then hopefully a lunar habitat.”

Herzig’s work on an inflatable moon habitat has been funded by the European Space Agency (ESA) and ESA’s Open Space Innovation Platform (OSIP), which funnels novel ideas into the agency.

“I hope one day we will really build this on the moon,” he says.

Jeff Moravec is a freelance writer based in Brooklyn Park, Minn.

Leave A Comment