Engineers from Japanese clothing company A-POC Able Issey Miyake and University of Tokyo startup Nature Architects Inc. Ltd. presented their innovative approach to the design process at this year’s Milan Design Week held April 17–23, showcasing how algorithms can be used to automate and streamline the process.

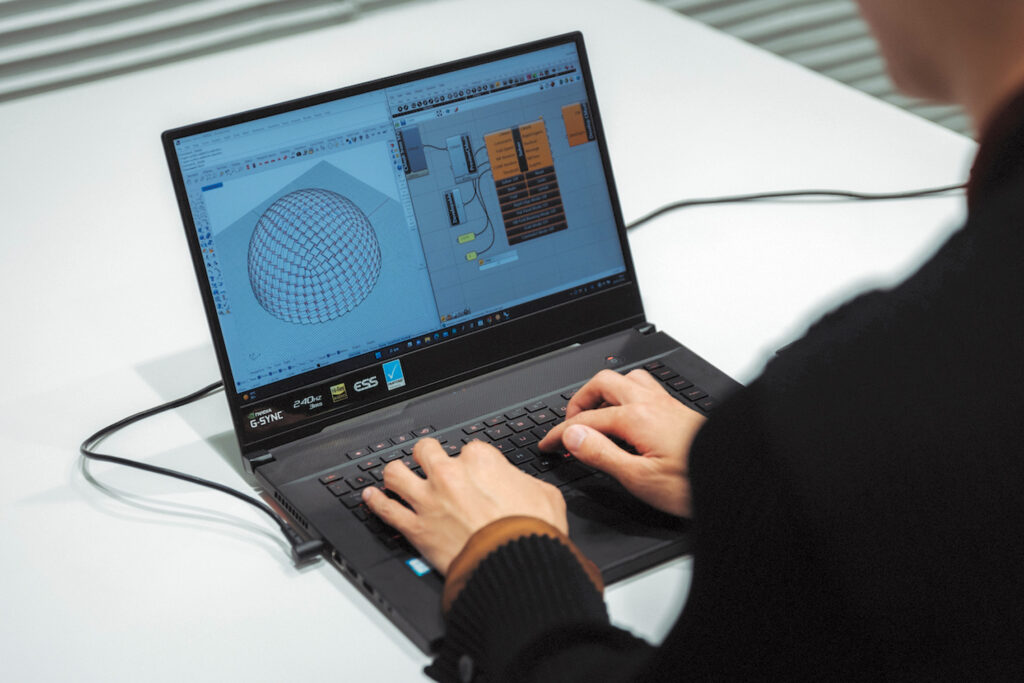

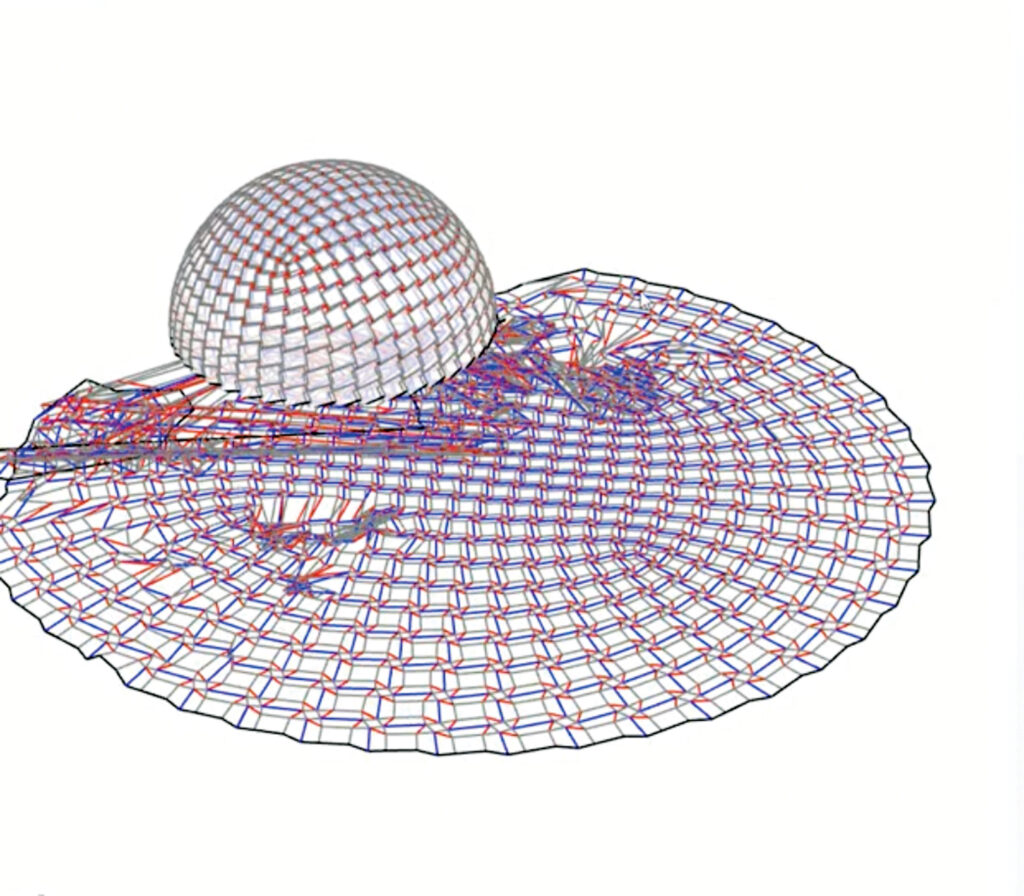

The companies used a direct functional monitoring (DFM) system, which uses algorithms to automatically generate a metamaterial unit structure and to determine where each unit will reside on the product’s outer diameter.

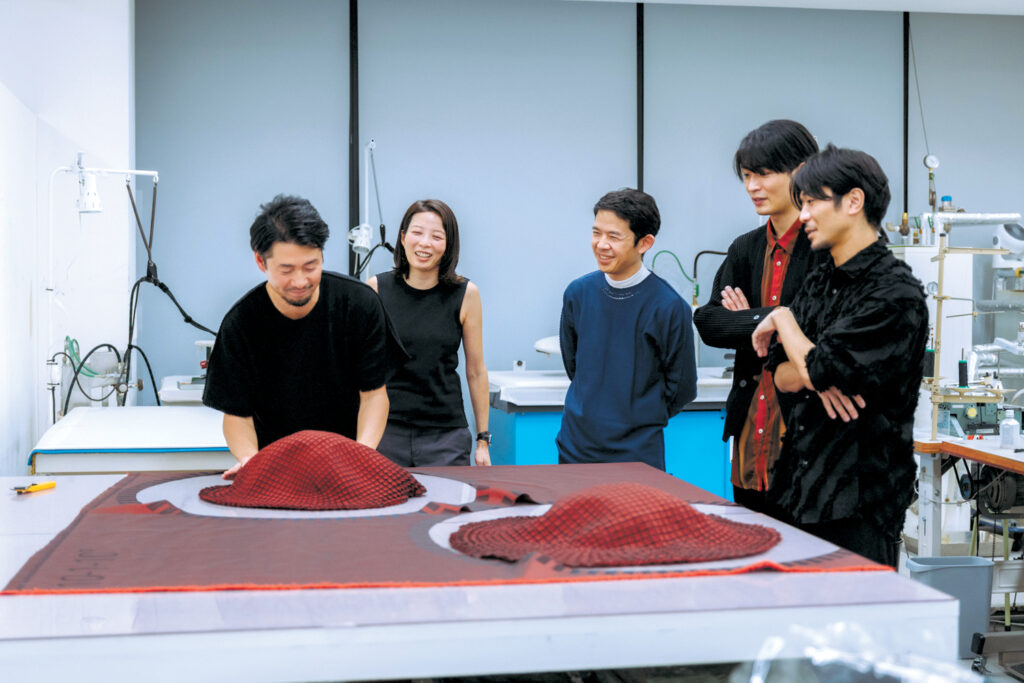

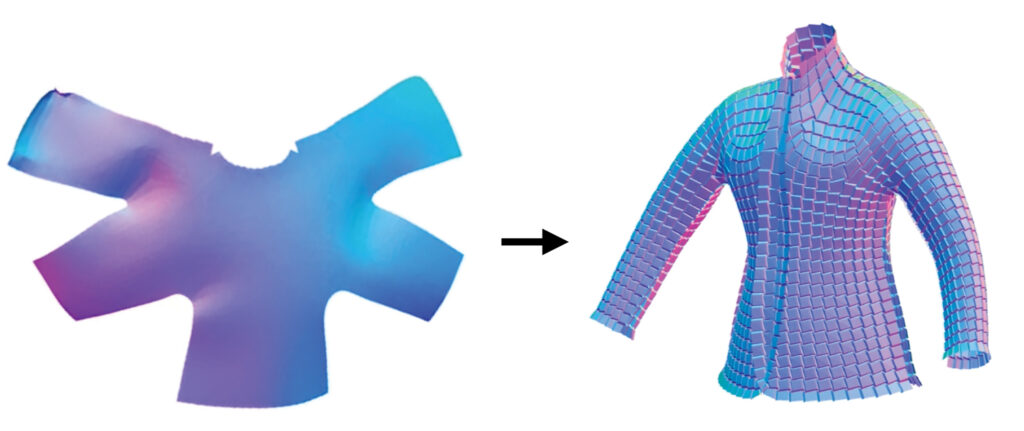

Using this technology, the companies created Steam Stretch, a fabric that transforms into 3D shapes when heat is applied.

The algorithm formed by the DFM first calculates the contraction pattern necessary to make the desired product and then generates a weaving diagram. Next, the algorithm targets specific threads for contraction to increase the fabric’s elasticity.

The project explores the vast design possibilities outside of the standard method of stitching together 2D fabrics, offering manufacturers a glimpse into what the future of textile production could hold.

According to their research, the technology has the potential to apply to sectors outside of apparel, such as furniture, lighting and architecture, among other uses.

For example, researchers found that it was possible to create shock-absorbing materials that could be used in vehicles to protect passengers during impact.

Nature Architects specializes in creating products with various functions, such as deformation, sound, vibration and heat, usually using plastics, rubber and metals. The company’s goal is to integrate parts and substitute materials to reduce production costs and increase sustainability within the textile industry.

Launched in 2021 by fashion designer Issey Miyake, A-POC Able Issey Miyake aims to further explore the possibilities of his 1997 apparel production concept known as A-POC, or A Piece of Cloth.

Leave A Comment